1

Each cast iron radiator section is meticulously checked for marks and imperfections. They are then fettled and rubbed down in preparation to be painted, polished or hand burnished.

2

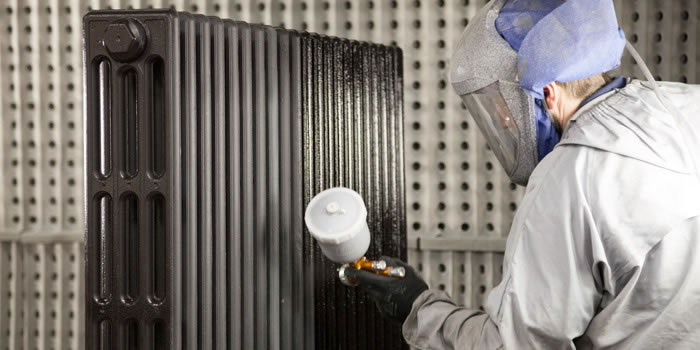

To achieve a highly durable paint finish, we first prime and paint all the radiator sections individually, assuring each section is evenly covered.

3

Particular attention is required when hand burnishing and highlighting each section of the radiators.

4

The radiator sections are then assembled by hand. The sections are held together using connectors & high quality seals.

5

All our radiators are put through vigorous and robust testing. A continuous high pressure is applied for a minimum of 24 hours at a rate well beyond that of normal water pressure found in UK domiciles.

6

A final round of painting or hand polishing is carried out to perfectly finish the radiators and safeguard a high quality finish.

7

Once completed the radiators are inspected and given a QC stamp of approval where they are placed on a pallet and boxed ready for dispatch.